CHANGSHENG GEO-MATERIAL TECHNOLOGY CO. LTD.

One of new technology powered with Changsheng Plastic Circular Loom

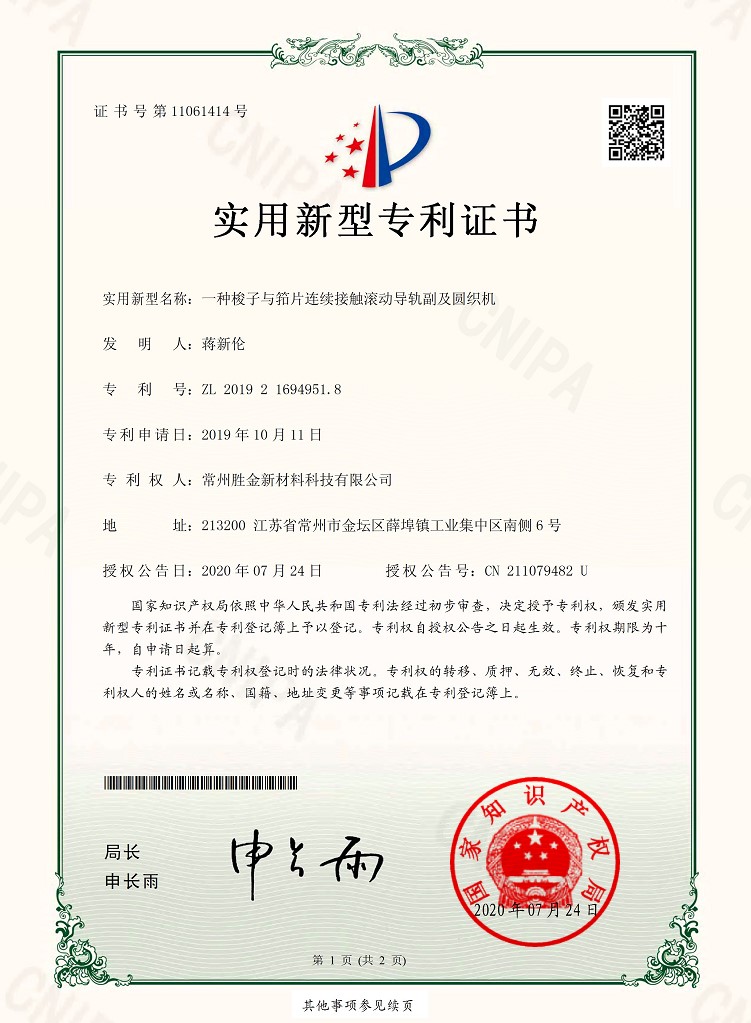

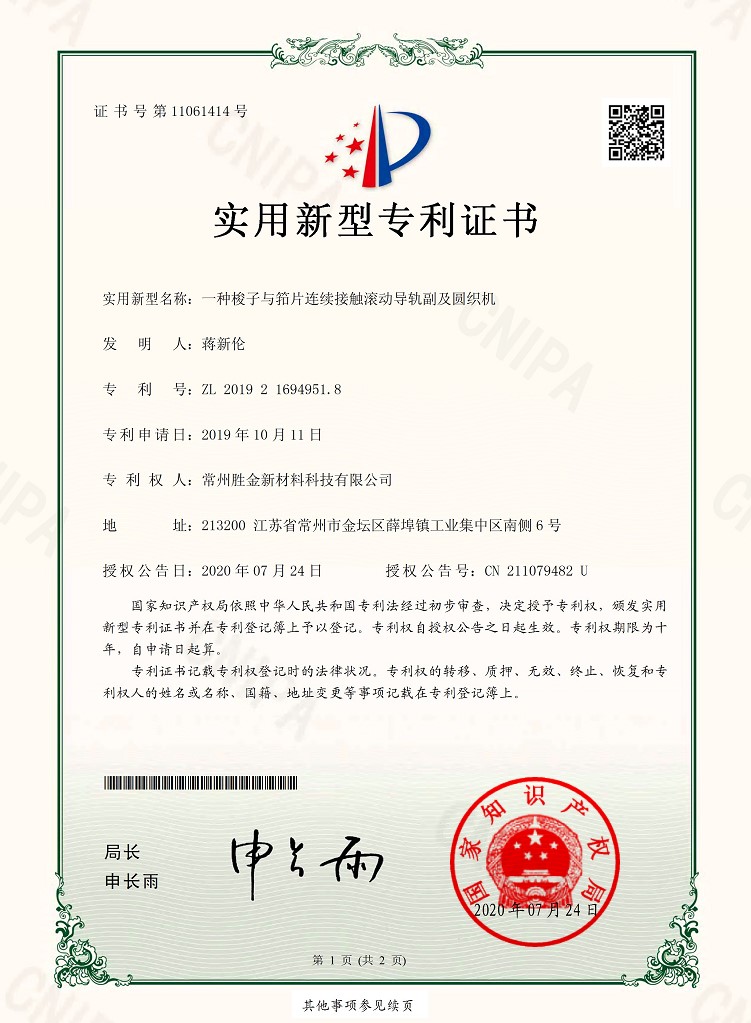

One kind of continuous contact rolling guide rail pair and circular Loom

Patent No. ZL 2019 2 1694951.8

Aug.22,2023

The composite of shuttle and shuttle track of current large-scale circular loom has three typical structures and the features stated as follows:

- Full shuttle wheel, shuttle back wheel rolling on un-continuous reeds causing jittering ,features low speed, big noise, short life of wheel , and shuttle easy rushing out.

- Upper-lower shuttle plus shuttle back skateboard structure, when shuttle back skateboard skating on un-continuous reeds causing plenty of heat due to sliding friction, so sliding face needs oil lubricating, sliding friction is applicable to lower speed, and has an high energy consumption.

- Dovetail groove skateboard shuttle track structure, shuttle back skating in un-continuous dovetail groove reeds with high reliability, but producing plenty of heat due to sliding friction so sliding face needs oil lubricating, it’s also applicable to lower speed, and has an high energy consumption.

Whereas defects in above three typical structures, we designed new structure featuring long wheel on shuttle back rolling continuously on inner cylindric surface composed by man-type reeds, during shuttle running, long wheel on shuttle back always keeping pure rolling without jittering and achiving benefits include:

- weaving speed increased 20% compared to traditional circular loom

- complete no oil lubricating between shuttle and shuttle track, lower operating cost, no oil pollution, exempted cumulation of greasy dust, greatly reduce daily cleaning and maintenance, especially applicable to weaving food grade fabric;

- low noise, significantly improve working circumstance ;

- low energy consumption, 15% lower electric current of main machine for same shuttle picking rate;

- long life of long wheel on shuttle back and man-type reeds.

| |

New Technology in ChangSheng Circular Loom

2022.11

|

| No |

New Patent/Technology |

Patent No.

|

Effects After Applied

|

| 1 |

A kind of shuttle against reeds continuing contacting and rolling guide rail pair and circular loom |

ZL 2019 2 1694951.8 |

Not using slide board, roll with back of shuttle,no oil in shuttle track,significant increase on shuttle speed, no heat-up, low noise, clean circumstance, makes production environment friendly

|

| |

|

|

|

| 2 |

A kind of pusher of shuttle and circular loom

|

ZL 2021 2 0564408.7 |

realize pure rolling of pusher friction wheel, pressure of friction wheel on track auto-fit with shuttle push force,no spring to pull, no skidding, so no heat-up basically,increase reliability and working life

|

| |

|

|

|

| 3 |

A kind of circular loom with air-cooling unit |

ZL 2020 2 2279389.1 |

warp may not be burnt without oil, helpful to enhance speed of circular loom, realize clean circumstance, no greasy and dust during weaving, makes production environment friendly

|

| |

|

|

|

| 4 |

A kind of warp anti-break reed, loop shuttle track and circular loom |

ZL 2021 2 1372322.0 |

lower fuzziness and broken of warp |

| |

|

|

|

| 5 |

SPCL8/4400 main drive: timing belt drive

|

|

electric current 8.0A when 60rpm,power about 3.5kw high drive efficiency,low power cost,no oil, convenient maintenance

|

| |

|

|

|

| 6 |

warp tensioning mechanism

|

Apply No. 202222285064.3 |

put an end of impact of warp up-shelf to weaving , stable and uniform tension of warp, thread can be pulled in jumper bar, convenient operating, reduce loss of raw material, increase qualified yield and output.

|

| |

|

|

|

CHANGSHENG GEO-MATERIAL TECHNOLOGY CO. LTD.

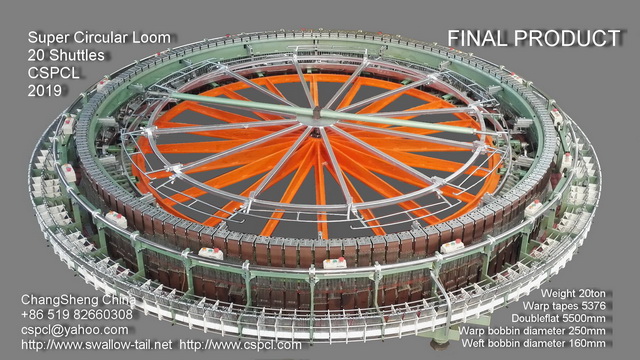

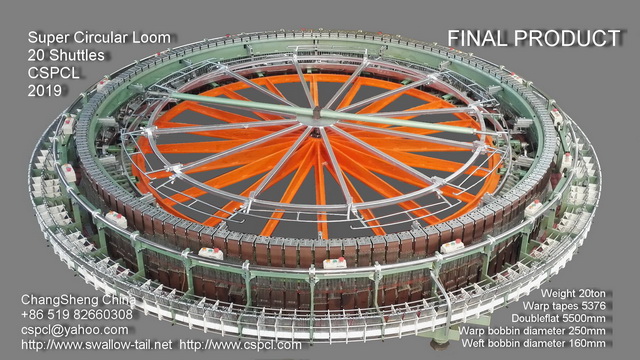

First 20-Shuttle Circular Loom Shipped to Oversea

Feb. 2019

Our new style twenty-shuttle shuttle-wheel-free circular loom manufactured for oversea's customer was shipped just days before lunar new year 2019 , the machine can weave plastic tape fabrics with perimeter 11m (doubleflat 5.5m)

SPCL-20/11000 Main specification

Shuttles 20

Main rpm 28

Doubleflat 5500mm

Warp tapes 5376

Tape tube ¢50x240

Weft bobbin diameter ¢160x220mm

Warp bobbin diameter ¢250x220

Main motor power 22kw

Lift motor power 2kw

Total weight 20000kg

Dimension (L x W x H) 22550x19720x7500

Updated : the 20s circular loom finished installatoin entered into production period

|

CHANGSHENG GEO-MATERIAL TECHNOLOGY CO. LTD.

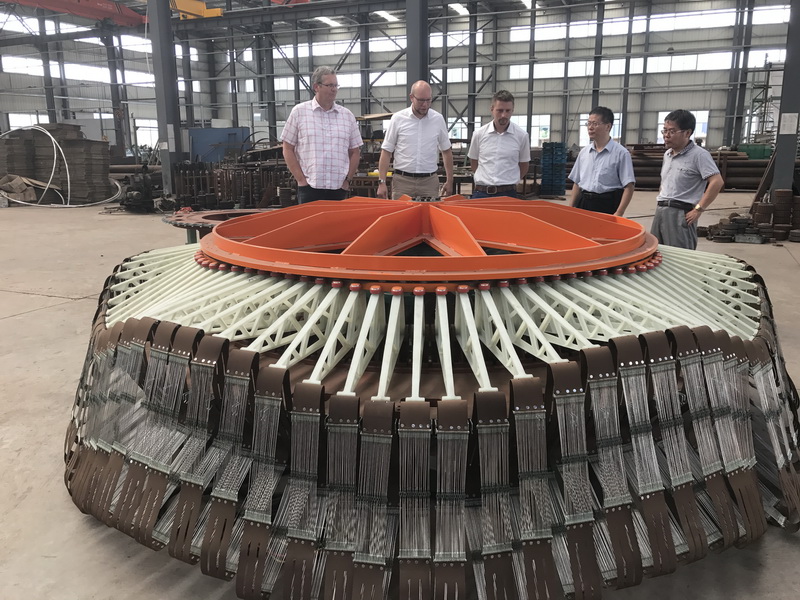

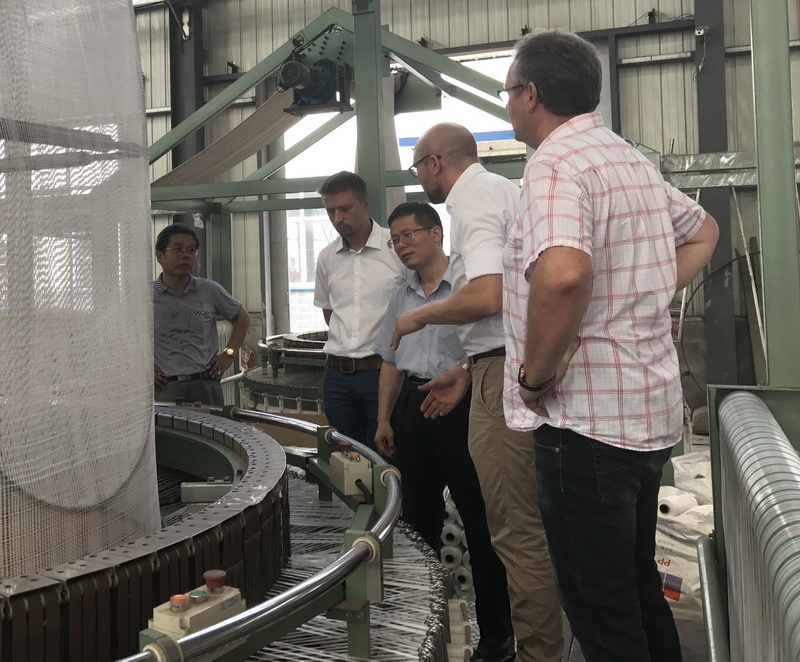

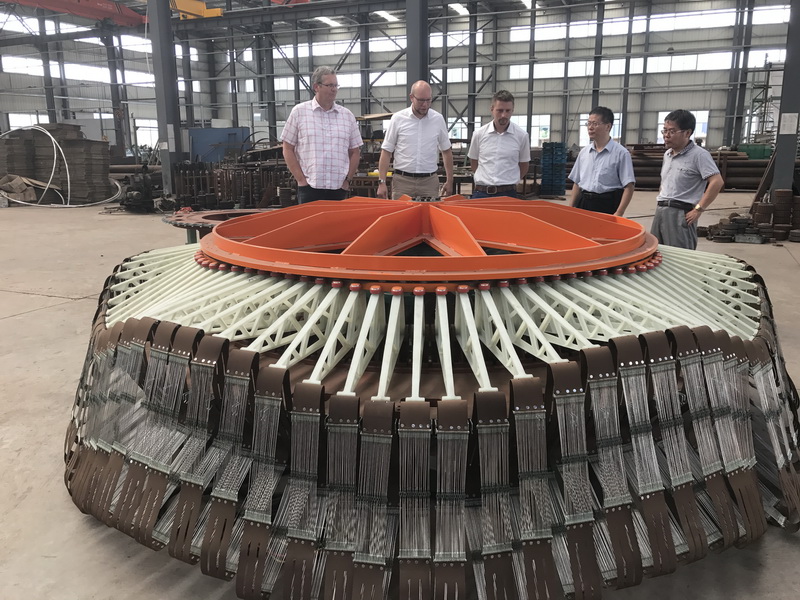

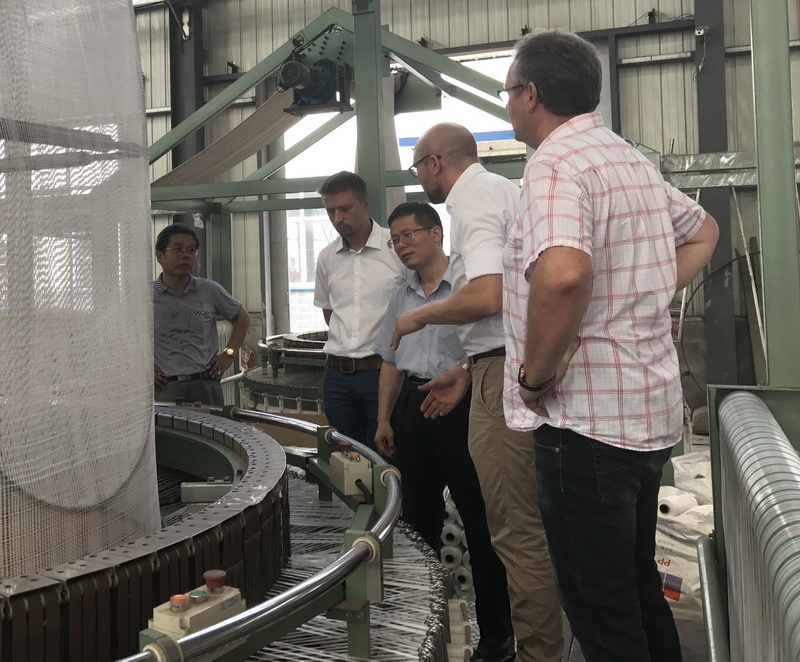

German Experts Visited Changsheng Circular Loom

|

|

August 2017

|

|

Three senior experts in geo-synthetics production and application industry from Germany visited our company to learn advanced technology of plastic circular loom, found our technology fresh and new, and quite impressed for heavy-duty circular loom which capable of weaving fabrics beyond 1000g/m2 and strength exceeding 400kN/m. We also hold friendly talks and discussions.

|

|

|

|

|

CHANGSHENG GEO-MATERIAL TECHNOLOGY CO. LTD.

The Ultimate Difference Between SPCL Series Circular Loom And Other Kinds Of Circular Loom

|

|

Nov 2009

|

|

|

The successful development of SPCL Plastic Circular Loom is the result of combining professional technology with patented technology and weaving experience, and is of full intellectual properties, the prominent performance are widely accepted by the market, nevertheless somebody still has questions like what differences are there between SPCL Series Plastic Circular Loom and other kinds of circular loom ? Here are our answers to two types of customers about the ultimate differences .

First of all we categorized customers as two types, the first type is the customers specialized in plastic weaving industry for a long-term period while another type is the customers ready to partake in plastic weaving industry.

The answers to first type of customers:

1.About Shuttle

Due to the unique patent (Swallow-Tail Guide Rail Pair for Plastic Circular Loom, Patent No ZL 96 2 17570.6 ) owned by SPCL Series Circular Loom, there’s only one wheel pushed by shuttle-pusher but no other wheels, the grind breakage to warps is reduced by 80% , meanwhile the impact of warps to movement precision of shuttles is avoided, these are completely different from all other kinds of circular loom, and result in following effects:

a) Significantly reducing thread breakage, the maximum width of the circular loom can be up to 10 meters over, unit weight of fabrics can be 250~800g/sq.m. or below 50g/sq.m.;

b) Completely avoiding shuttle drop, and the shuttle can be adapted to warps with thickness above 0.03-0.5mm;

c) Strength loss of fabrics decreased by 10%.

2. About Cam

SPCL Series Circular Loom improved on 3-dimension cam adopted by STARLINGER Circular Loom (Austria ) , there are no friction distances and no any other parts within the open-mouth formed by cam, rocker and palm belt, bestowed the whole machine with following characters:

a) stable running, no lubrication needed for cam, low noise;

b) power consumption decreased by more than 25%, or power-saving 60 degrees a day for 6m width circular loom.

3. About Weft Density Adjustment

SPCL Series Circular Loom adopting transducer and servo-control on main machine and lifting system to keep the synchronization between lifting speed and rotating speed of main machine, and the speed ratio can be adjusted as required at any moment, as a result:

a) precise adjustment of fabrics unit weight can be made at any moment, as such to remedy slit films’ error on drawbench, so as to meet customer’s requirement and avoid waste of slit film;

b) no need to stop machine while adjusting weft density, adjusting while weaving is necessary to high productivity.

The answers to second type of customers:

1. About Performance of SPCL Series Super Circular Loom

a) SPCL Series Circular Loom is the only circular loom covering width 2m to 10.2m and unit weight 40 g/sq.m. to 800g/sq.m., in other words SPCL Series Circular Loom can weave fabrics which other circular loom can weave , as well as weave the fabrics which other circular loom cannot weave so that usually obtains corner opportunities on the market.

b) Using same thread , the intensity of fabrics woven by SPCL Series Circular Loom is 10% higher than by other circular loom, i.e. if intensity of fabrics woven by other circular loom differentiates up to 10% from requirement, SPCL Series Circular Loom can still produce fabric with the intensity required, hence on a daily production , inferior fabrics can be reduced to the least and greatly cut down the case that users claim for compensation and cannot receive payment for poor product quality.

c) The rotation speed per minute of SPCL-16/10000, SPCL-12/8000A and SPCL-10/6000 is respectively 35, 41 and 51, less thread breakage, while weaving fabrics with density 10x10, 130g/sq.m., daily turnout is 14000sq.m. , 10000sq.m. and 8000sq.m. respectively.

2. About Maintenance

While striving for outstanding performance of SPCL Series Circular Loom we apply ourself to simplify maintenance and reduce easy-wear parts, skilled-workers with three years’ experience in machinery industry can master service technics with one month.

3. About After Service

We own the all core technologies of SPCL Series Circular Loom, while improving our product we also extend the service to old customers to enhance the performance of all SPCL Series Circular Loom for maximum benefits.

|

|