CHANGSHENG GEO-MATERIAL TECHNOLOGY CO. LTD.

One of new technology powered with Changsheng Plastic Circular Loom

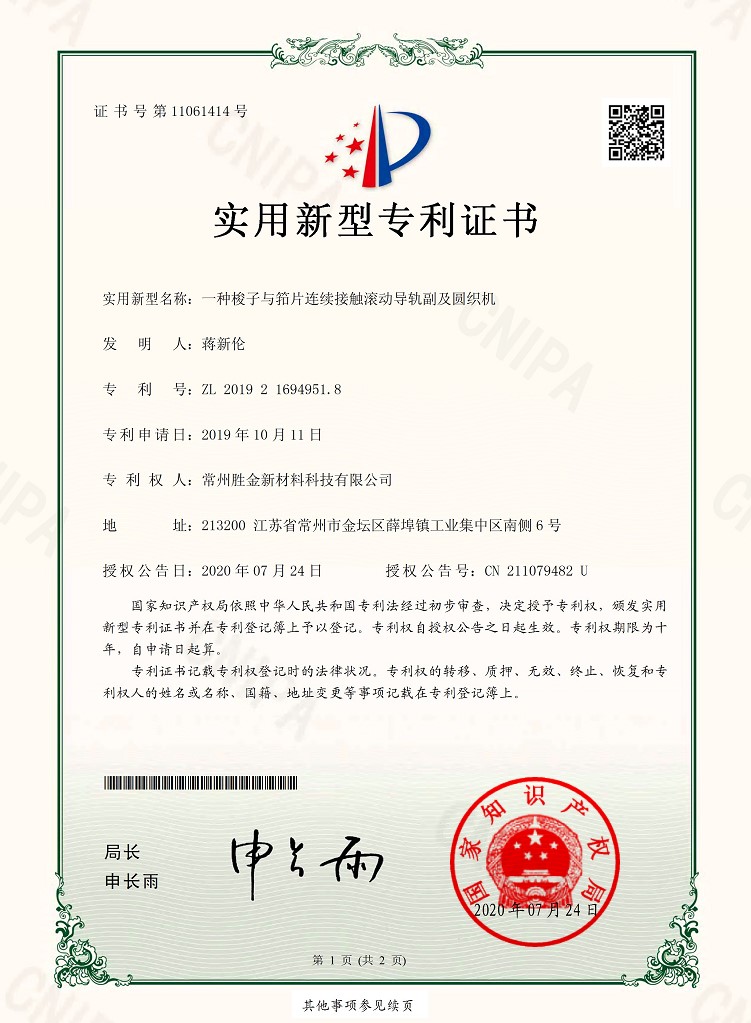

One kind of continuous contact rolling guide rail pair and circular Loom

Patent No. ZL 2019 2 1694951.8

Aug.22,2023

The composite of shuttle and shuttle track of current large-scale circular loom has three typical structures and the features stated as follows:

- Full shuttle wheel, shuttle back wheel rolling on un-continuous reeds causing jittering ,features low speed, big noise, short life of wheel , and shuttle easy rushing out.

- Upper-lower shuttle plus shuttle back skateboard structure, when shuttle back skateboard skating on un-continuous reeds causing plenty of heat due to sliding friction, so sliding face needs oil lubricating, sliding friction is applicable to lower speed, and has an high energy consumption.

- Dovetail groove skateboard shuttle track structure, shuttle back skating in un-continuous dovetail groove reeds with high reliability, but producing plenty of heat due to sliding friction so sliding face needs oil lubricating, it’s also applicable to lower speed, and has an high energy consumption.

Whereas defects in above three typical structures, we designed new structure featuring long wheel on shuttle back rolling continuously on inner cylindric surface composed by man-type reeds, during shuttle running, long wheel on shuttle back always keeping pure rolling without jittering and achiving benefits include:

- weaving speed increased 20% compared to traditional circular loom

- complete no oil lubricating between shuttle and shuttle track, lower operating cost, no oil pollution, exempted cumulation of greasy dust, greatly reduce daily cleaning and maintenance, especially applicable to weaving food grade fabric;

- low noise, significantly improve working circumstance ;

- low energy consumption, 15% lower electric current of main machine for same shuttle picking rate;

- long life of long wheel on shuttle back and man-type reeds.